MIL-DTL-3124E(SH)

3.3.11.7 Generators with frame sizes not less than 200 kilowatts at 1800 r/min and all generators using bus bar

in lieu of cable. Terminal boards need not be provided. The leads shall be clamped into position so that strain from

the outside cannot be transmitted to the connections within the generator frame. The leads shall be of sufficient

length to facilitate making connections and shall be provided with a means for making connections to the ship

cables. Terminal lugs shall not be provided.

3.3.11.7.1 Bus bar leads. Bus bar leads shall be in accordance with 3.3.11.3.

3.3.11.8 Terminal markings. When facing the opposite drive end, terminals shall be marked T1, T2, T3

reading from front (the end opposite the drive) to back, right to left, or top to bottom. Direct current (DC) field leads

shall be marked F1 and F2. A labeled schematic vector placard shall be mounted on the generator, showing

inverted-wye windings or delta windings, as appropriate.

3.3.11.9 Minimum radius of cable bend. The location of connections and clearances shall be such that

specified cable can be installed using the minimum radius of bend in accordance with MIL-DTL-24643. As

construction design guidance, Type LSTSGU cable in accordance with MIL-DTL-24643/16 is shown for selected

size cables, with recommended current-carrying capacities and minimum radius of bend:

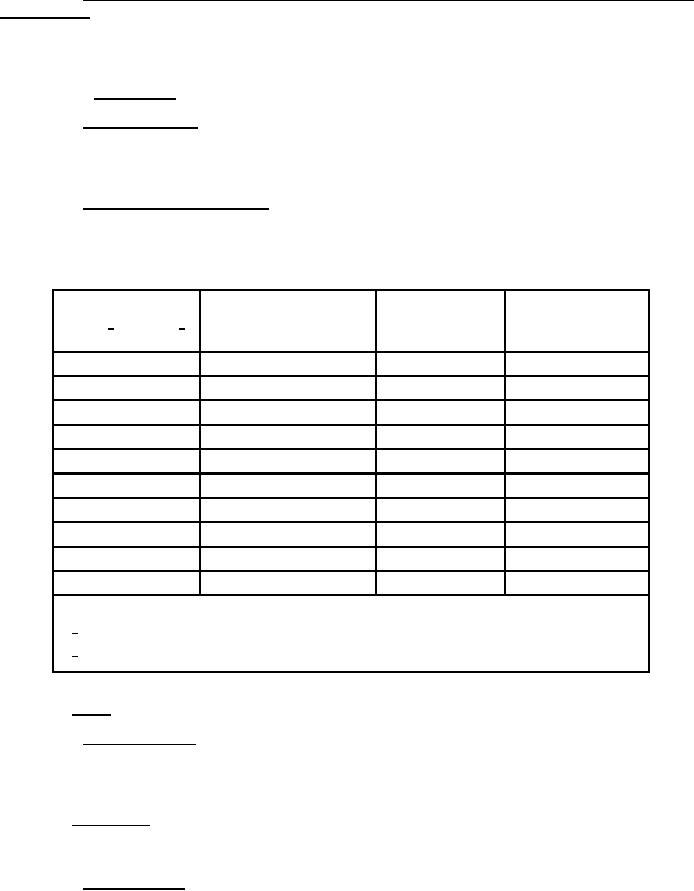

Current rating

Cable overall

Minimum allowable

Wire size,

(amperes) at

maximum

radius for cable

MCM 1/ or AWG 2/

60 Hz and 122 °F (50 °C)

diameter (inches)

bend (inches)

16

10

0.411

3.5

14

17

0.449

3.5

10

36

0.575

4.5

9

47

0.718

5.5

7

64

0.812

6.5

3

101

0.969

8.0

1

136

1.134

9.0

000

216

1.515

12.0

300

320

1.957

15.5

400

400

2.203

17.5

NOTES:

1/

MCM is the old abbreviation for one thousand circular mils.

2/

AWG is the abbreviation for American wire gauge.

3.3.12 Frame. The frame shall be of rigid construction, either integral with the support structure or detachable.

3.3.12.1 Detachable frames. Detachable frames shall have feet large enough to accommodate holding-down

bolts, dowel pins, and jackscrews, where used, to ensure attachment to the common bedplate or to the structural

foundations of the vessel, as required. The frame feet shall be machined and drilled for holding-down bolts. Fitted

bolt holes shall be left with an allowance for reaming at time of installation of generator with prime mover.

3.3.13 End brackets. Where end brackets are used, a machined shoulder joint shall be provided between the

frame and the end brackets. End brackets shall be secured to the frame by not less than four hexagon-head bolts or

cap screws of suitable size and strength.

3.3.13.1 Resilient gaskets. Resilient gaskets shall not be placed between any bearing support members and the

frame.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business