MIL-DTL-3124E(SH)

3.3.19.3.2 RTE lead wire connection. The RTE lead wires that connect to the monitor shall be brought through

a radially drilled 0.187-inch maximum diameter hole and channeled into a groove (approximately ⅛ by 3/16 inch)

connecting the radial hole with a connection block recessed in bearing within 30 degrees of the bearing part line. An

air hardening epoxy-resin or room temperature hardening (RTV) silicone, following the guidance provided in

MIL-HDBK-298, shall be applied in the groove to protect the wiring. The wires shall be soldered or room

temperature hardened (RTV), following the guidance provided in MIL-HDBK-298, to the connection block.

3.3.19.3.3 Pivoted shoe bearing. The procedures specified in 3.3.19.3.1, 3.3.19.3.2, and 3.3.19.3.4 for sleeve

bearings shall generally apply for installing RTEs in pivoted shoe bearings, except that the RTE shall be installed at

the trailing edge of one lower shoe, and the bearing connection block shall be recessed in the edge or end of the shoe

on the pivot line.

3.3.19.3.4 Connection block wiring. Wiring between the bearing connection block and the casing (or bearing

pedestal) wall shall be required to complete the circuit. The wiring shall be recessed in epoxy-resin-filled grooves,

in holes, or in an armored sheath to prevent damage in accordance with MIL-E-917; additional guidance can be

found in MIL-HDBK-298. The wiring shall be easily disconnected (mechanically or by melting soft solder) from

the bearing connection block and shall penetrate the casing wall through a Type AN connector in accordance with

SAE-AS50151. Location of connectors shall minimize damage to the attached connector and cables. Penetration

points shall be oiltight if the internal surfaces of these points are subject to being submersed or splashed with oil.

3.3.19.3.5 Caution plate. A caution plate, warning that the RTE wires to bearings shall be disconnected before

rolling out the bearing, shall be permanently affixed to the external top of the bearing cap. A similar caution plate

shall also be installed on the generator where disassembly of the generator could result in damage to the RTE

arrangement installed in the generator stator and cooling air sections. Label plates shall be anodized-hydrated

aluminum in accordance with ASTM B209, manufactured in accordance with MIL-DTL-15024, Type H, and shall

have black letters on a background color of natural anodized-hydrated aluminum.

3.3.19.3.6 Terminal box. Wiring from RTEs shall be brought out to a dripproof-protected terminal box as

specified in 3.3.4. The external wiring from RTEs to the terminal box shall be firmly supported and protected by

rigid or flexible conduit.

3.3.20 Bedplate bolting. When generator bolt holes, provided for securing the generator to the bedplate, are

used with dowels and non-fitted bolts, such bolts shall be in accordance with Types I, II, or III, Grade 5 of

MIL-DTL-1222, and self-locking nuts shall be in accordance with NASM17828 and NASM17829. Bolts of higher

grade may be used with NAVSEA approval. Clearance between bolt holes and bolts shall be not greater than the

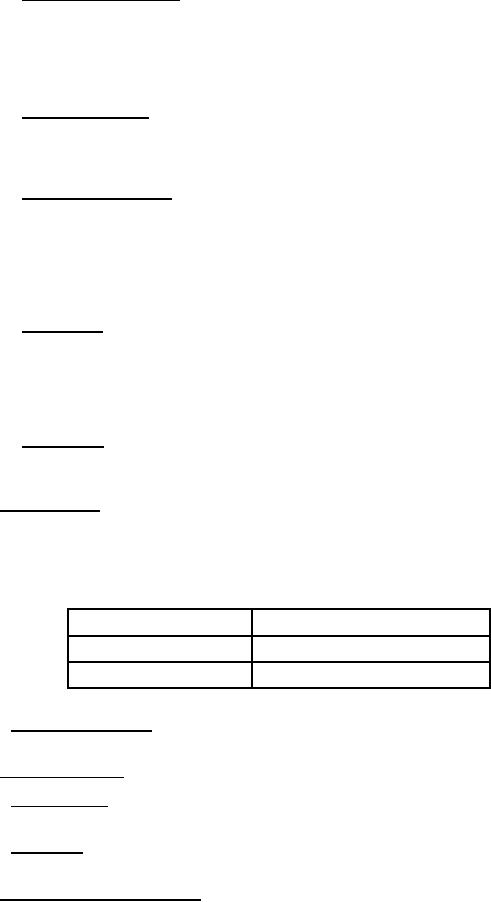

following:

Nominal bolt diameter

Maximum diameter of holes

Nominal bolt diameter plus 1/32 inch

¾-inch or smaller

Nominal bolt diameter plus 1/16 inch

Larger than ¾-inch

3.3.20.1 Rigidly supported units. Rigidly supported units shall not be attached to two structures which can

deflect relative to each other under shock.

3.3.21 Welding and casting. Welding and casting shall be in accordance with S9074-AR-GIB-010/278.

3.3.21.1 Welding review. When S9074-AR-GIB-010/278 requires review of specific aspects of welding and

allied processes, the reviewing activity shall be NAVSEA.

3.3.21.2 Stress relief. Welded rotating parts of the generators shall be stress relieved. Stationary parts shall be

stress relieved in accordance with S9074-AR-GIB-010/278.

3.3.22 Creepage and clearance distances. Creepage and clearance shall be in accordance with the requirements

of MIL-E-917.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business