MIL-DTL-62186C

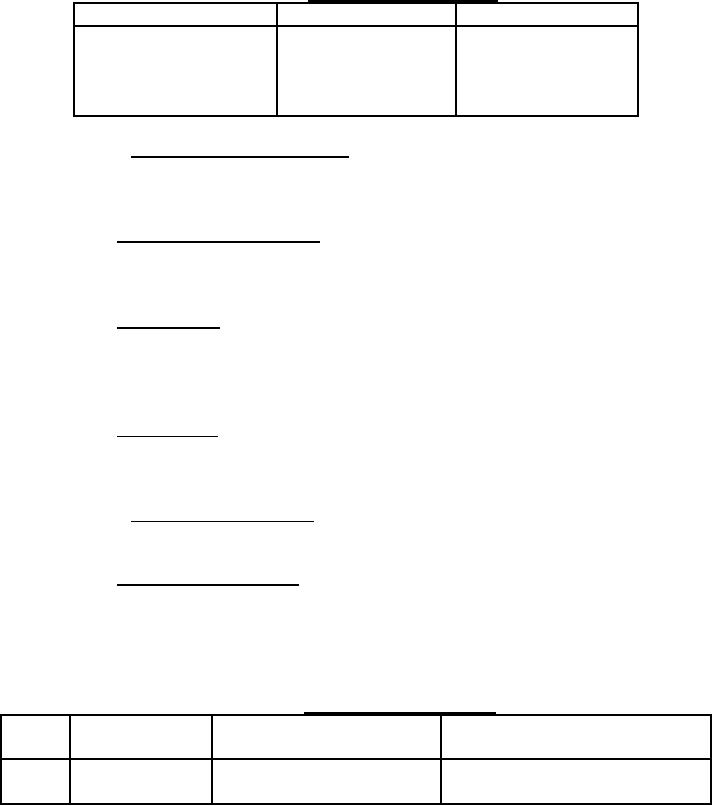

TABLE IV. Ripple voltage conditions.

Condition (rpm)

Load (A)

Regulated volts

28 0.5

a. 3000

50

28 0.5

b. 3000

650

28 0.5

c. 8000

50

28 0.5

d. 8000

650

4.3.5.5.1 Ripple voltage acceptance test. Connect the alternator to a test circuit as

specified in figure 11. With the alternator operating as specified in table IV, condition (d), the

ripple voltage shall be not more than 4 V (+peak -peak and peak-to-peak).

4.3.5.6 Overload output current test. Connect the alternator to a test circuit as specified

in figure 10. Operate the alternator at 5000 rpm with an output power of 800 25 A (IA) at not

less than 23 Vdc (EA) for 30 seconds. The field current (IF) shall be not less than 4 A.

4.3.5.7 AC signal test. Connect the alternator to a test circuit as specified in figure 10.

Apply 20 2 Vdc to the alternator field at pin C to pin A at the J2 connector. At alternator

speeds of 900 rpm and 1100 rpm, the AC signal voltage (EAC) at pin A to pin C at the J1

connector shall be 7.1 0.5 V rms and 8.9 0.5 V rms, respectively.

4.3.5.8 CT signal test. Connect the alternator to a test circuit as specified in figure 10.

Operate the alternator at 8000 rpm with a power output of 650 A (IA) and 28 Vdc (EA). The CT

signal (ECT) at the J1 connector from pin B to pin C shall be 2.8 +0.2, -0.3 V rms.

4.3.5.8.1 CT signal acceptance test. Operate the alternator as in 4.3.5.8. The CT signal

(ECT) at the J2 connector from pin B to pin C shall be 2.8 +0.2, -0.3 V rms.

4.3.5.9 Alternator oil system test. Connect the alternator to a test circuit as specified in

figure 10. With no electrical load, and with alternator speed, alternator outlet pressure (P2), and

oil inlet pressure as specified in table V, the oil flow (F1) shall be not less than 2.35 gal/min

(0.15 L/s), nor greater than 6.0 gal/min (0.38 L/s). The oil pump outlet pressure (P1) shall be not

greater than the proof pressure.

TABLE V. Oil system test conditions.

Alternator speed

Alternator outlet pressure

Test

(rpm)

(P2)

Alternator oil inlet pressure

-0.385 0.03 psi (-2.7 0.2 kPa)

1

2000 and 8000

5 psi (34.5 kPa) maximum

45 2 psi (310 13.8 kPa)

2

2000 and 8000

5 psi (34.5 kPa) maximum

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business