MIL-DTL-62186C

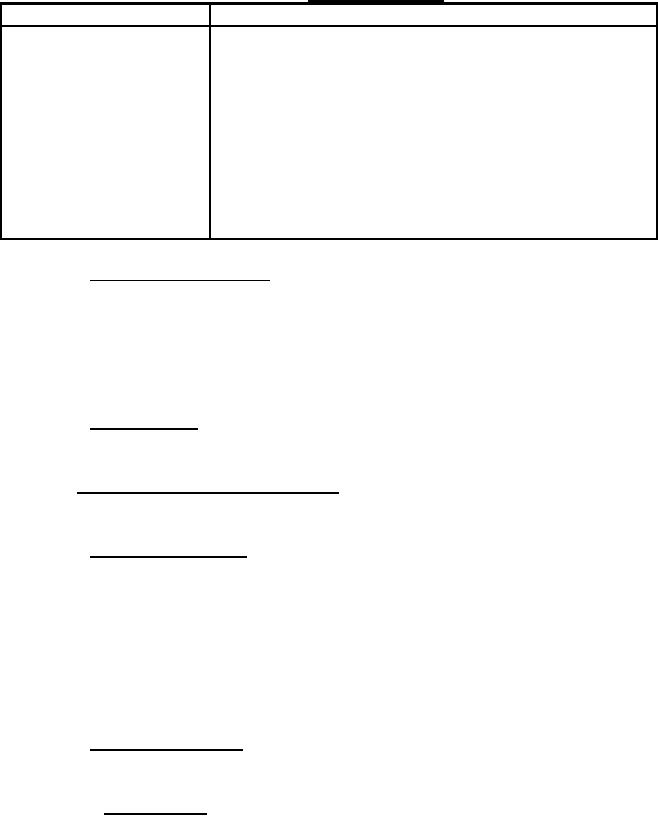

TABLE VI. Oil contamination.

Test hours

Oil contamination

Start of 600 hour cycle

Add 3.2 grams (g) of SOFTC-2A per 5 gallons (gal) of oil

in oil system.

At 200 hours

Add 3.2 g of SOFTC-2A per 5 gal of used oil already in

system.

At 400 hours

Add 3.2 g of SOFTC-2A per 5 gal of used oil.

Total contamination now 9.6 g SOFTC-2A per 5 gal.

At 600 hours

Drain used oil and grit out of system. Thoroughly flush oil

and grit from system with solvent. Use air to thoroughly

dry system. Refill system per "start" for next 600 hour

period, as applicable.

4.3.7.2 Endurance operation test. When specified (see 6.2), install the alternator on an

engine-transmission conforming to Drawing 11655426. Operate the engine-transmission

assembly to provide alternator performance in accordance with the conditions as specified in

4.3.7.1 and tables I and II, twice running through a, b, c, and d, in sequence, for a total of

48 endurance hours. The alternator shall exhibit no indication of failure, fracture, distortion,

erosion, or other evidence of deterioration.

4.3.7.3 Nameplate test. Visually inspect nameplate for permanent and legible

identification marking.

4.3.8 Operating environment verifications. Complete and pass the tests as specified in

4.3.8.1 through 4.3.8.6.

4.3.8.1 High temperature test. Fill the alternator oil circuits with MIL-PRF-2104,

grade 40. Subject the unit to a high temperature test in accordance with procedure II,

method 501.3 of MIL-STD-810, or equivalent (see 4.3.1), except that 36 hours of storage at

225F (107C) shall be substituted for steps 1 through 6, and steps 7 through 11 shall be

performed at standard ambient conditions. When stabilized at the 225F (107C) operational

temperature, the unit shall be subject to and pass the tests as specified in 4.3.5.1, 4.3.5.4, 4.3.5.7,

4.3.5.8, and 4.3.5.9 without evidence of damage. The same tests are to be repeated during the

ambient operational test.

4.3.8.2 Low temperature test. Perform each low temperature test as specified in

4.3.8.2.1 and 4.3.8.2.2.

4.3.8.2.1 Cold soak test. Fill the alternator oil circuits with MIL-PRF-46167 prior to

start of cold soak test. The alternator shall be subject to a low temperature storage test at

-65 5F (-54 2.8C) for 12 hours. At the conclusion of the cold soak test, the alternator and

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business