MIL-DTL-62186C

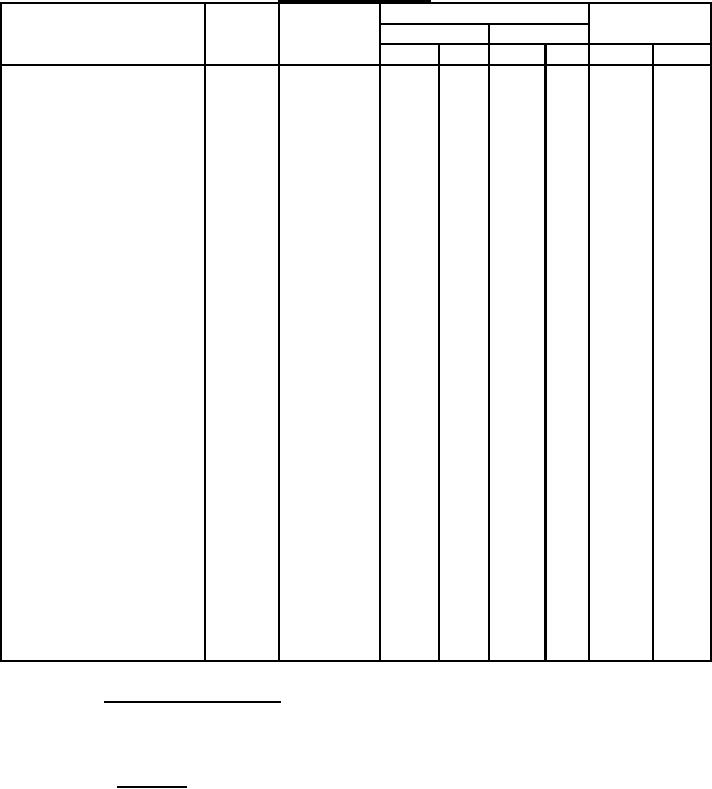

TABLE III. Verification methods - Continued.

First article inspections

Require-

Inspec-

PPI sample

IPI sample

Conformance

Title

ment

tion

1

2

1

2

Exams 100%

CT signal

3.4.8

4.3.5.8,

X

X

X

X

X

Acceptance

4.3.5.8.1

X

Alternator oil system

3.4.9

4.3.5.9

X

X

X

X

X

X

Transient load

3.4.10

4.3.5.10

X

X

Efficiency

3.4.11

4.3.5.11

X

X

Proof pressure

3.4.12

4.3.5.12,

X

X

X

X

Acceptance

4.3.5.12.1

X

Torsion

3.4.13

4.3.5.13

X

EMI

3.4.14

4.3.5.14

X

3.5

4.3.6

Interface requirements

Installation compatibility

3.5.1

4.3.6.1

X

X

X

Regulator

3.5.2

4.3.6.2

X

X

X

Weight

3.5.3

4.3.6.3

X

X

X

X

3.6

4.3.7

Support and ownership

requirements

Endurance

3.6.1

4.3.7.1,

X

4.3.7.2

Nameplate

3.6.2

4.3.7.3

X

X

X

3.7

4.3.8

Operating environment

requirements

High temperature

3.7.1

4.3.8.1

X

X

Low temperature

3.7.2

4.3.8.2

X

X

Shock

3.7.3

4.3.8.3

X

X

Vibration

3.7.4

4.3.8.4

X

X

Waterproofness

3.7.5

4.3.8.5

X

X

X

X

Humidity

3.7.6

4.3.8.6

X

Aqueous salt environment

3.7.7

4.3.8.7

X

Fungus resistance

3.7.8

4.3.8.8

X

4.1.2 Conformance inspection. Unless otherwise specified (see 6.2 and 6.4), each

alternator shall be tested for the 100% conformance tests as specified in table III. Samples

selected as specified in 4.1.2.1 shall be verified as specified in table III.

4.1.2.1 Sampling. The sampling plan shall be as specified in the contract (see 6.2).

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business